Turning and Milling Processing Services

We specialize in CNC turning and milling of various metal parts, equipped with vertical lathes, horizontal lathes, machining centers, and multi-station composite machines. This enables us to efficiently complete precision machining of various rotating bodies, shaft parts, disc parts, flange parts, and shell parts, widely used in industries such as construction machinery, energy equipment, hydraulic systems, and transmission systems. According to customers’ drawing requirements, we provide single-piece sampling, small-batch production, and customized processing for complex parts.

Typical Machined Products

Various flanges (slip-on weld, butt weld, large-diameter)

Hydraulic cylinder barrels, oil cylinder end covers

Slewing bearing bushings, positioning rings, seal seats

Motor housings, gearbox end covers

Large disc parts, shaft parts, sleeve parts

Overview of Machining Capabilities

Equipment Configuration:

CNC Horizontal Lathes

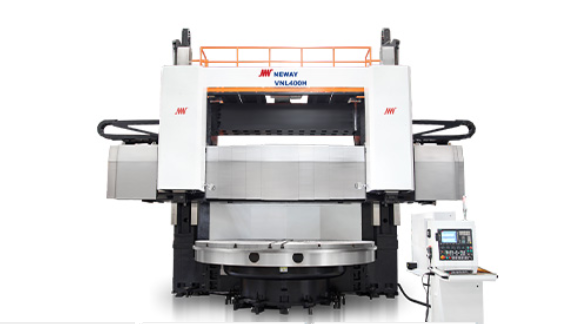

CNC Vertical Turning Lathes (VTLs)

Gantry Machining Centers

CNC Machining Centers (3/4/5-Axis)

Boring Mills

Precision Drilling Machines

Machining Capabilities:

Max Turning Diameter: Ø2000mm

Max Processing Length: 9000mm

Integrated Processing: Roughing → Semi-Finishing → Finishing (Turnkey Solution)

Material Expertise:

Carbon Steel | Stainless Steel | Aluminum | Copper | Alloy Steel | Wear-Resistant Steel

Our Advantages

Manufacturing Process

Customer drawing confirmation and evaluation → Material procurement and blank preparation → Rough machining: preliminary forming with allowance reserved → Finishing: dimensional tolerance control and finishing of surface treatment areas → Inspection and deburring

Application Industries

The application industries include transmission system components for construction machinery, spare parts for energy equipment such as wind power and nuclear power, large rotating components for marine and offshore engineering, core components of hydraulic machinery and speed reducers, as well as parts for mining machinery and metallurgical equipment. These sectors all rely on our precision machining capabilities to obtain reliable components that meet their specific operational requirements in different industrial fields.